FirstElement opens world’s first commercial truck stop for hydrogen-fueled vehicles

FirstElement Fuels has opened the world’s first large-scale hydrogen fueling station for heavy trucks.

Located near the Port of Oakland, the station has capacity to fill 200 trucks a day in as little as 10 minutes per truck. There are 30 Hyundai Xcient trucks using the fueling station currently, as well as other Nikola hydrogen fuel-cell-electric trucks.

(Photo: FirstElement Fuels)

The first-of-its-kind filling station for zero-emission hydrogen trucks was opened to the public this week for tours and demonstrations. Whisper-quiet hydrogen-fueled trucks pulled into the station for a quick fill-up before returning to their actual drayage operations.

This is the vision of Shane Stephens, one of the company’s founders and its chief development officer, who along with two other founders created FirstElement to address issues related to a lack of hydrogen fueling infrastructure.

“The last remaining hurdle is the infrastructure and that’s why we created this company, to tackle that problem,” Stephens told visiting trade press media. “Over the past 10 years since our creation we have taken on a leadership role in creating commercially viable hydrogen fueling stations. The technology that was out there couldn’t scale, meet the needs of the public and it didn’t have the reliability to make it viable.”

A Hyundai FCEV is filled during a demonstration at FirstElement Fuels. (Photo: James Menzies)

A Hyundai FCEV is filled during a demonstration at FirstElement Fuels. (Photo: James Menzies)

The Port of Oakland station fills trucks at 700 bar (10,000 psi), enabling the fast fills drayage operators need without burdening California’s sometimes shaky electrical grid like battery-electric trucks would. Consider that 50 Class 8 battery-electric trucks would require 9 megawatts of charging capacity, which is equal to the power consumed by the Empire State Building.

Hyundai is an official partner in the project, contributing 30 trucks while Nikola drivers are also able to fuel at the station. Drivers arriving at the station swipe their fuel card, connect the nozzle to the truck, and in just a few minutes are ready to continue on their journey. Two trucks can be fueled simultaneously with gaseous hydrogen, but Stephens said the site was future-proofed to deliver liquid hydrogen if and when that demand exists.

Fueling trucks with liquid hydrogen provides even greater range and it’s a technology that was recently demonstrated by Daimler Truck and Air Liquide.

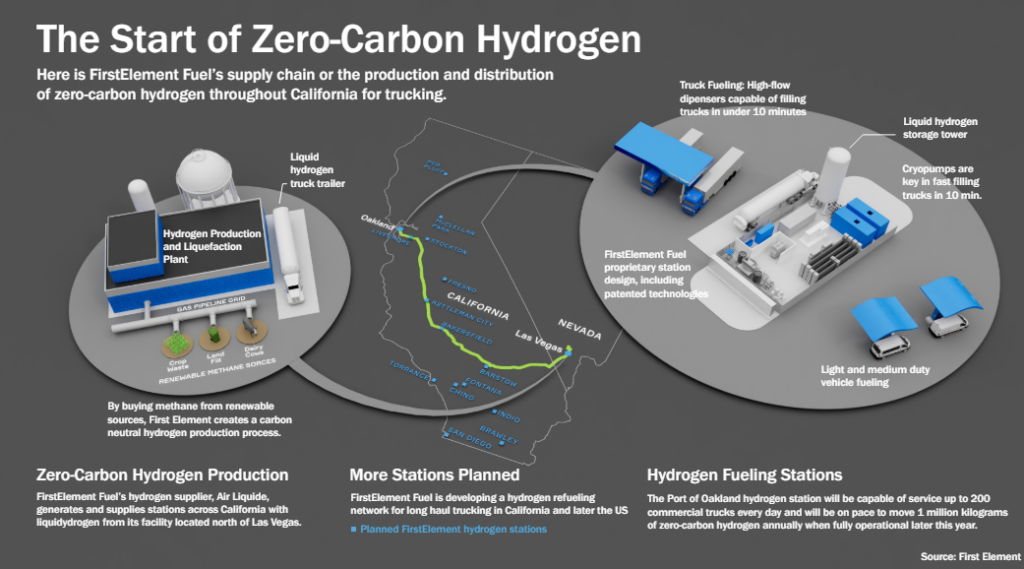

“We have plans to add other hydrogen stations up and down California to create a network up and down all the trucking routes,” said Stephens.

Bosch’s Dave Hull (left) and FirstElement’s Shane Stephens explain how the cryopump (in the background) technology works at FirstElement’s Livermore, Calif., proving grounds. (Photo: James Menzies)

Bosch’s Dave Hull (left) and FirstElement’s Shane Stephens explain how the cryopump (in the background) technology works at FirstElement’s Livermore, Calif., proving grounds. (Photo: James Menzies)

A major enabler of the fast filling capabilities is new high-volume cryopump technology developed by Bosch Rexroth. Those pumps are being validated and FirstElement has its Port of Oakland truck stop plumbed in to be upgraded when those cryopumps are ready for commercial rollout.

“That technology was critical to unlock the scale, volume and efficiency needed to fuel vehicles with larger tanks,” Stephens said.

The truck stop concept marks a major milestone for the clean fuel. FirstElement’s first hydrogen station had one dispenser and could fill just one car at a time, or 200 kg a day. The truck stop will be capable of delivering 18,000 kg a day – almost 100 times the capacity of the first station. While this is the largest commercial truck hydrogen truck stop in the world, Stephens said it will likely be the smallest going forward as FirstElement grows its network.

It has a 10-year agreement with Nikola to supply its trucks there, as well as the 30 Hyundais that are part of the program. Jerome Gregeois is director of commercial vehicle development at Hyundai America Technical Center.

He said the hydrogen fuel-cell-electric truck is part of the company’s efforts to be carbon-neutral by 2045. Just 15 trucks will consume the hydrogen that 700 passenger cars would require, he noted.

The Xcient is a 6×4 cabover tractor with storage capacity for 68 kg of hydrogen. The fuel cells feed a 72-kWh battery pack and a 350-kW motor with 1,650 lb.-ft. of torque, providing about a 450-mile (720-km) range. Hyundai hasn’t yet announced any formal plans to produce Class 8 trucks for the North American market, but it’s clearly interested.

Hyundai is studying the idea of bringing its fuel cell trucks to the North American market. (Photo: James Menzies)

Hyundai is studying the idea of bringing its fuel cell trucks to the North American market. (Photo: James Menzies)

“Obviously, North America is a huge market,” Gregeois said. “It’s the largest trucking market in the world. We are studying opportunities in the market and we have these trucks here to better understand their performance and sustainability, and which applications they’d work for.”

The hydrogen is produced by Air Liquide in Las Vegas using natural gas as a feedstock. It is trucked to the fueling station as a liquid. “Our hydrogen is all certified to be zero carbon or carbon neutral from well to wheel through the entire supply chain,” Stephens said.

FirstElement purchases biogas to blend with the natural gas to create hydrogen that’s more than 60% renewable and qualifies as ‘green.’

So far, the station has completed more than 200 demonstration fills on heavy-duty trucks. More than 2,000 kg of hydrogen has been dispensed over the past 30 days while commissioning the station. Another commercial fueling station is located in Livermore, Calif. The 2.5-acre facility also serves as a proving grounds and is where testing of Bosch’s new cryopump technology is underway.

Dave Hull, regional vice-president, Bosch Rexroth, said the cryopump will allow for filling at 900 bar (15,000 psi), enabling the trucks to be filled in just a few minutes. It will allow fills of 100 kg in just 10 minutes. The cryopump, with its ability to fuel trucks with liquid hydrogen could also potentially eliminate a lot of complexity and additional storage tanks.

Bosch even has plans to use the cold that’s generated by the hydrogen.

“Cold is like gold,” said Hull. “You’ve got all this cold energy. All my career I worked to get rid of heat. You can take that energy and run a while station’s refrigerators for Rock Star energy drinks, or air conditioning. Bosh has a whole division of heat pumps and building technologies.”

Over the course of the six-year project, more than 50 million pounds of CO2 will be eliminated, and 2 million gallons of diesel fuel will go unconsumed. Another 300,000 lb. of other pollutants such as NOx will also be eliminated with just the 30 trucks involved in the project.

For Stephens, the time is right for hydrogen to be widely adopted as a commercial transportation fuel. “We, at FirstElement Fuels, have a lot of confidence the market is coming,” he said. “We see the regulations on the horizon, the OEMs and fleet owners are going to have to respond to that, especially when it comes to goods movement, and hydrogen and fuel cells are the best – if not only – solution that will work for many of those use cases.”